Steps to brewing beer

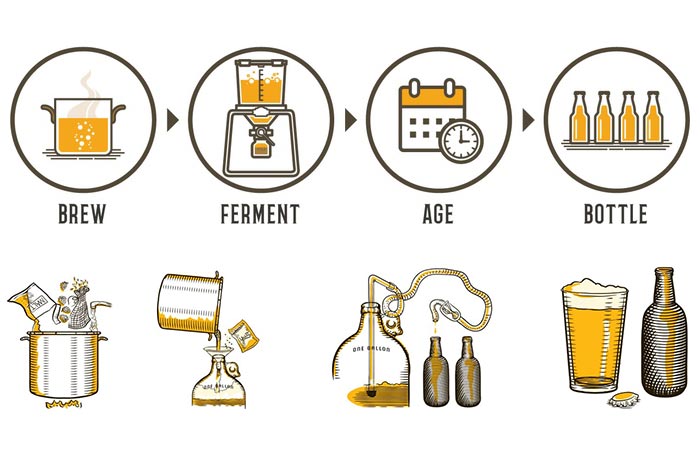

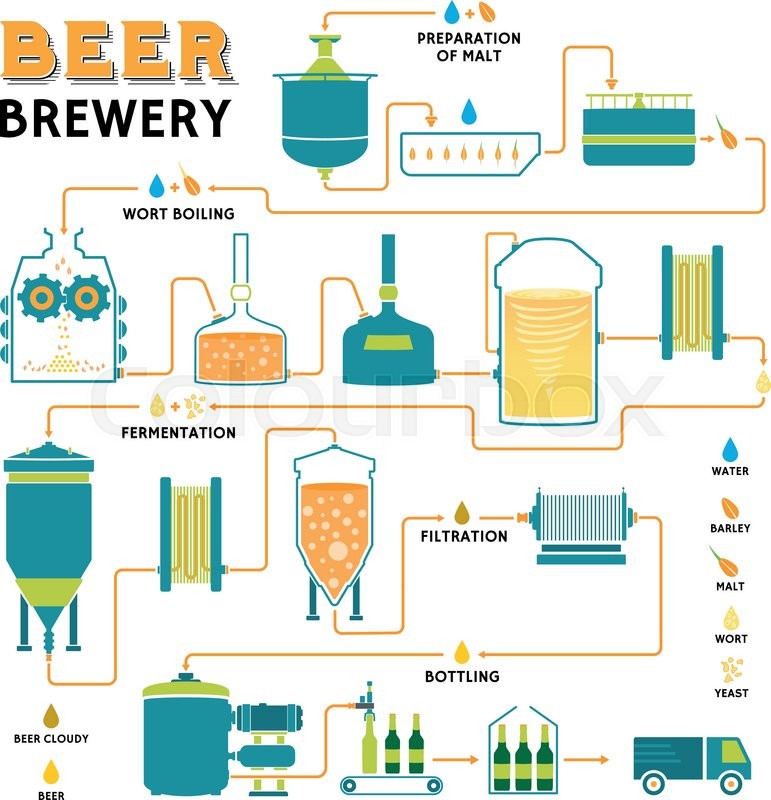

Steps To Brewing Beer. Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm. The Start of the Brewing Process Brewing beer involves liquid transfer at both hot and cold temperatures. Carbonate the beer forcefully by compelling the keg with carbon dioxide gas. Filtration carbonation and cellaring After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete.

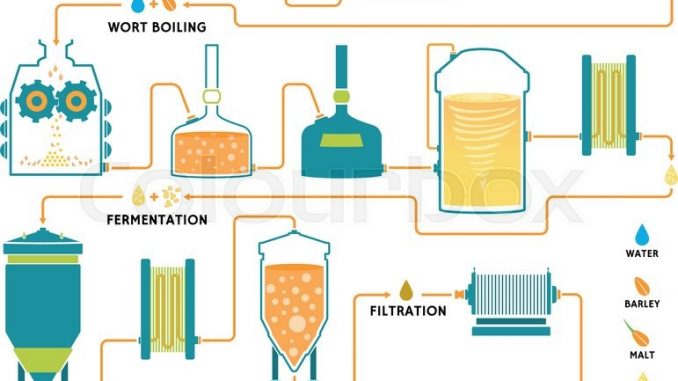

The Process Of Brewing Beer Visual Ly From visual.ly

The Process Of Brewing Beer Visual Ly From visual.ly

The mash is filtered in the lauter tun as the husks sink and the wort is separated from the solid substances spent grains. Beer Brewing Process Malting Raw barley is heated and dried with the crushing of the grain. Experiment with dry-hopping for different aromas change the yeast for a more estery beer ferment at lower temperatures for a cleaner brew. The Start of the Brewing Process Brewing beer involves liquid transfer at both hot and cold temperatures. The choice is yours. Attach bottle filler to hose and hose to bottling bucket spigot.

Beer is produced from barley grains.

The fourth step in the production of beer is lautering. Open the bottling bucket spigot and. The process of the yeast metabolization is what will turn wort the liquid extracted from the mashing process into beer. Yeast is the secret to turning a brew into beer. Steps involved in beer production are. Experiment with dry-hopping for different aromas change the yeast for a more estery beer ferment at lower temperatures for a cleaner brew.

Source: researchgate.net

Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm. You can do this by attaching the quick-disconnect to the gas-in valve of the keg. Use a hose sprayer to sprinkle the mixture over your lawn. And for those of us who are partial to a nice pint of scrumpy Turbo Cider is possibly the drink for you. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100.

Source: shutterstock.com

Source: shutterstock.com

Use a hose sprayer to sprinkle the mixture over your lawn. Filtration carbonation and cellaring After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete. Leave as much sediment in the fermenter as possible. Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm. Beer is produced from barley grains.

Source: pinterest.com

Source: pinterest.com

Attach bottle filler to hose and hose to bottling bucket spigot. The Start of the Brewing Process Brewing beer involves liquid transfer at both hot and cold temperatures. The transferring of liquid at these different temperatures is known as hot process and cold process At the beginning of this process mash wort or. Carbonate the beer forcefully by compelling the keg with carbon dioxide gas. Yeast is a living microorganism that will metabolize the sugars from the grains and creates alcohol and carbon dioxide.

Source: visual.ly

Source: visual.ly

When we moved house a few years ago the equipment never got unpacked and it seemed easier just to go down to the bottle shop and buy a carton although he always says it doesnt taste as good. Filtration carbonation and cellaring After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete. After fermentation the young green beer needs to be matured in order to allow both a full development of flavors and a smooth finish. Yeast is the secret to turning a brew into beer. Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm.

Source: pinterest.com

Source: pinterest.com

Filtration carbonation and cellaring After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete. The barley grains are then passed through grist mills to form grits. Open the bottling bucket spigot and. Beer Brewing Process Malting Raw barley is heated and dried with the crushing of the grain. The transferring of liquid at these different temperatures is known as hot process and cold process At the beginning of this process mash wort or.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Beer Brewing Process Malting Raw barley is heated and dried with the crushing of the grain. Once the pressure releases to the keg you will hear a hissing sound. Follow these simple steps. I bought Brewing Beer 4 Simple Steps about a week ago this for my husband who used to enjoy brewing his own beer. The aim of malting is to isolate the enzymes needed for brewing.

Source: birrificio.it

Source: birrificio.it

The fourth step in the production of beer is lautering. Experiment with dry-hopping for different aromas change the yeast for a more estery beer ferment at lower temperatures for a cleaner brew. The Start of the Brewing Process Brewing beer involves liquid transfer at both hot and cold temperatures. Open the bottling bucket spigot and. Filtration carbonation and cellaring After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete.

Source: 123rf.com

Source: 123rf.com

Leave as much sediment in the fermenter as possible. Attach bottle filler to hose and hose to bottling bucket spigot. The process of the yeast metabolization is what will turn wort the liquid extracted from the mashing process into beer. Follow these simple steps. Once the pressure releases to the keg you will hear a hissing sound.

Source: pinterest.com

Source: pinterest.com

The barley grains are then passed through grist mills to form grits. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100. Combine a few drops of dishwashing liquid molasses ammonia liquid lawn food and a can of beer. Yeast is the secret to turning a brew into beer. The Start of the Brewing Process Brewing beer involves liquid transfer at both hot and cold temperatures.

Source: jebiga.com

Source: jebiga.com

The transferring of liquid at these different temperatures is known as hot process and cold process At the beginning of this process mash wort or. Use a hose sprayer to sprinkle the mixture over your lawn. Once the pressure releases to the keg you will hear a hissing sound. Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm. Once the beer gets into the keg seal it with the lid.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

I bought Brewing Beer 4 Simple Steps about a week ago this for my husband who used to enjoy brewing his own beer. It differs from other industrial fermentation because flavor aroma clarity color foam production foam stability and percentage of alcohol are the factors associated with finished product. The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. Yeast is a living microorganism that will metabolize the sugars from the grains and creates alcohol and carbon dioxide. Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm.

Source: aslanbrewing.com

Source: aslanbrewing.com

The mash is filtered in the lauter tun as the husks sink and the wort is separated from the solid substances spent grains. Combine a few drops of dishwashing liquid molasses ammonia liquid lawn food and a can of beer. Carbonate the beer forcefully by compelling the keg with carbon dioxide gas. The barley grains are then passed through grist mills to form grits. And for those of us who are partial to a nice pint of scrumpy Turbo Cider is possibly the drink for you.

Source: foodcrumbles.com

Source: foodcrumbles.com

The process of the yeast metabolization is what will turn wort the liquid extracted from the mashing process into beer. Once the beer gets into the keg seal it with the lid. Brewing is a complex fermentation process. Leave as much sediment in the fermenter as possible. The mash is filtered in the lauter tun as the husks sink and the wort is separated from the solid substances spent grains.

![]() Source: northernbrewer.com

Source: northernbrewer.com

Follow these simple steps. Siphon the beer out of your fermenter and into your bottling bucket. Follow these simple steps. After fermentation the young green beer needs to be matured in order to allow both a full development of flavors and a smooth finish. And for those of us who are partial to a nice pint of scrumpy Turbo Cider is possibly the drink for you.

Source: vectorstock.com

Source: vectorstock.com

Filtration carbonation and cellaring After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete. Well Im pleased to say that these Brewing Beer tips have re-ignited his enthusiasm. The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. The choice is yours. Follow these simple steps.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title steps to brewing beer by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.