Steps to brew beer

Steps To Brew Beer. Lagering begins from day 24 to around day 50. Make sure they are proper beer bottles other bottlescontainers may be lible to explode under the carbon dioxide that will be produced within the bottle. Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat. As the polyphenols coalesce and fall at the bottom the beer becomes clearer and tastier.

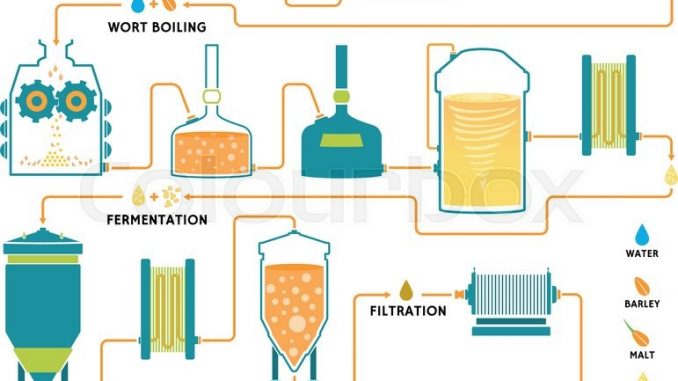

Beer Brewing Process Brewery Factory Production Vector Image From vectorstock.com

Beer Brewing Process Brewery Factory Production Vector Image From vectorstock.com

Barley grains are first cleaned and then soaked in water for about 2 days. Carbonating sugars are a mixture of 3-4 ounces of corn sugar and 1 or 2 cups of water. How to Make Beer Step 1. Add half a teaspoon of demerera sugar into each bottle. Beginning In the brew house different types of malt are crushed together to break up the grain kernels in order to extract fermentable sugars to produce a milled product called grist. The mixture is poured into the brew kettle and the beer is siphoned back into the kettle.

This equipment feeds the malt through a shaft in which multiple hammers pulverize the grain kernels.

The conversion process uses natural enzymes in the malt to break the malts. The beer is siphoned into the bottles up to an inch from the top. Beer Brewing Steps Step 1. Your business name your company logo your business website design your beer can or label designs and your brewpub or tap house decor should all grow from the concepts you layout here. After that time the beer. Beer is produced from barley grains.

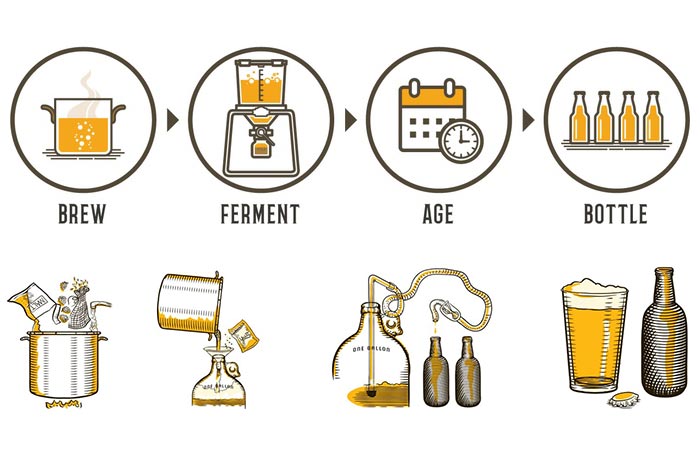

Source: avopix.com

Source: avopix.com

And maintain that brand as your craft beer business evolves and grows. As the polyphenols coalesce and fall at the bottom the beer becomes clearer and tastier. Dont forget to. Your business name your company logo your business website design your beer can or label designs and your brewpub or tap house decor should all grow from the concepts you layout here. How to Make Beer Step 1.

Source: aslanbrewing.com

Source: aslanbrewing.com

First transfer half a gallon of wort to a bucket or other container and then pour it back to the mash tun. Fill your 5-gallon brew kettle with 25 gallons of water. Your business name your company logo your business website design your beer can or label designs and your brewpub or tap house decor should all grow from the concepts you layout here. The mixture is poured into the brew kettle and the beer is siphoned back into the kettle. Beer is produced from barley grains.

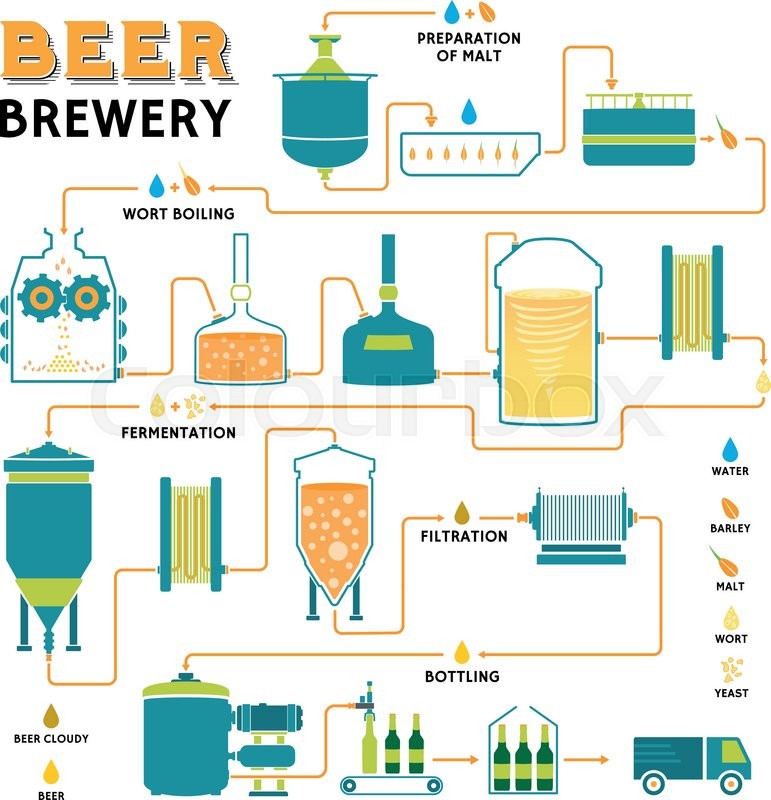

Source: vectorstock.com

Source: vectorstock.com

And maintain that brand as your craft beer business evolves and grows. The mixture is poured into the brew kettle and the beer is siphoned back into the kettle. This consistency of brand personality and the quality of your beer. Make sure they are proper beer bottles other bottlescontainers may be lible to explode under the carbon dioxide that will be produced within the bottle. Dont forget to.

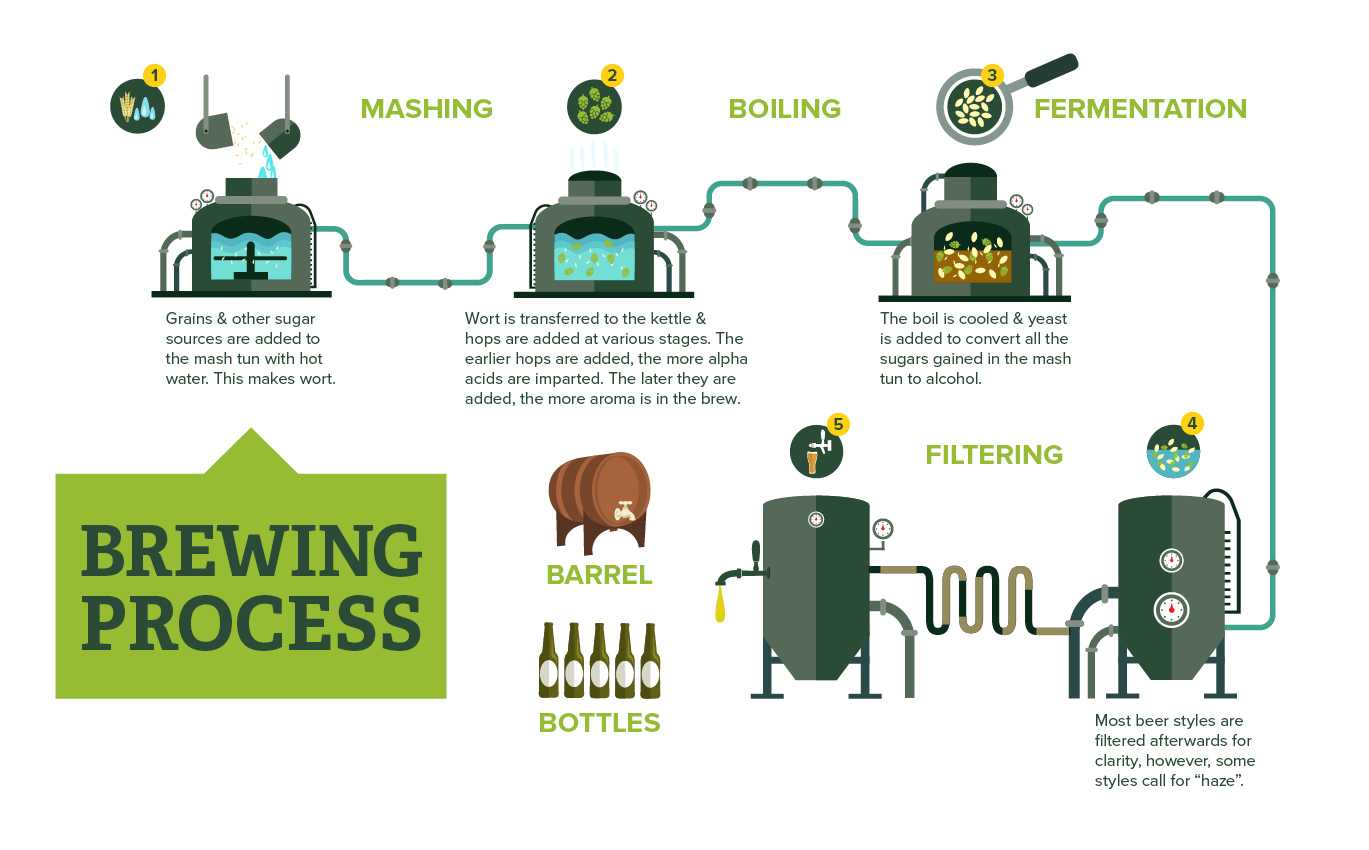

Source: pinterest.com

Source: pinterest.com

The beer is siphoned into the bottles up to an inch from the top. So take the time to think really think about your brand from the start. Malt in beer must be pressed very finely so the producers employ hammer mills. This equipment feeds the malt through a shaft in which multiple hammers pulverize the grain kernels. Beer Brewing Steps Step 1.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Buy all equipment needed for your operations. Stomping or kneading the banana mixture into the stiff grass releases the clear banana juice that will be used in the fermentation process to brew the beer. This consistency of brand personality and the quality of your beer. Fill your 5-gallon brew kettle with 25 gallons of water. Then excess water is drained away and the barley are incubated for 4-5 days to allow germination.

Source: vectorstock.com

Source: vectorstock.com

At the brewery the malt is sent through a grist mill cracking open the husks of the kernels which helps expose the starches during the mashing process. And maintain that brand as your craft beer business evolves and grows. So take the time to think really think about your brand from the start. Carbonating sugars are a mixture of 3-4 ounces of corn sugar and 1 or 2 cups of water. As the polyphenols coalesce and fall at the bottom the beer becomes clearer and tastier.

![]() Source: northernbrewer.com

Source: northernbrewer.com

Dont forget to. Now you will do the actual sparging or cleansing. Beer Brewing Steps Step 1. Dont forget to. The conversion process uses natural enzymes in the malt to break the malts.

Source: jebiga.com

Source: jebiga.com

Then you will need to hold it on at this temperature for about 4 to 5 weeks. Place the pasty banana container full into a cheesecloth and squeeze out the juice into a catch jar. First transfer half a gallon of wort to a bucket or other container and then pour it back to the mash tun. The mixture is poured into the brew kettle and the beer is siphoned back into the kettle. Your business name your company logo your business website design your beer can or label designs and your brewpub or tap house decor should all grow from the concepts you layout here.

Source: 123rf.com

Source: 123rf.com

Your business name your company logo your business website design your beer can or label designs and your brewpub or tap house decor should all grow from the concepts you layout here. The conversion process uses natural enzymes in the malt to break the malts. This equipment feeds the malt through a shaft in which multiple hammers pulverize the grain kernels. Place the pasty banana container full into a cheesecloth and squeeze out the juice into a catch jar. There are three major phases in the brewing process.

Source: visual.ly

Source: visual.ly

How to Make Beer Step 1. As the polyphenols coalesce and fall at the bottom the beer becomes clearer and tastier. A capper seats the cap on the bottle and the bottles will sit for 2 to 3 weeks at room temperature. Bottling beer is time-consuming but it is much more cost-efficient than kegging. Add half a teaspoon of demerera sugar into each bottle.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Add your grain bag cover with the kettle lid and let everything steep for 30 minutes. Our goal is to brew about 5 gallons of beer so be sure to heat enough water to top up your wort with. Wort making is the step that requires the most work from the brewer as you make a perfect solution for brewers yeast to turn into tasty beer. Steps involved in beer production are. I used 15x 500ml beer bottles.

Source: pinterest.com

Source: pinterest.com

Steps involved in beer production are. Then excess water is drained away and the barley are incubated for 4-5 days to allow germination. When harvested grain maltusually barleyarrives at the brewing facility it is crushed into grist by mills to release its sugars. Dont forget to. Your business name your company logo your business website design your beer can or label designs and your brewpub or tap house decor should all grow from the concepts you layout here.

Source: pinterest.com

Source: pinterest.com

This equipment feeds the malt through a shaft in which multiple hammers pulverize the grain kernels. Use a funnel will make it easier. Make sure they are proper beer bottles other bottlescontainers may be lible to explode under the carbon dioxide that will be produced within the bottle. The process of steep milling or soaking the grain before milling is also an option for large-scale brewers. By this time you already have the beer perfectly fermented and its only time to refine the tastes and flavors.

Source: foodcrumbles.com

Source: foodcrumbles.com

Then excess water is drained away and the barley are incubated for 4-5 days to allow germination. So take the time to think really think about your brand from the start. The process of steep milling or soaking the grain before milling is also an option for large-scale brewers. Add half a teaspoon of demerera sugar into each bottle. Lower the temperatures slowly from 60 to between 30 and 40 F.

Source: usahops.org

Source: usahops.org

Make sure they are proper beer bottles other bottlescontainers may be lible to explode under the carbon dioxide that will be produced within the bottle. And maintain that brand as your craft beer business evolves and grows. Now you will do the actual sparging or cleansing. At the brewery the malt is sent through a grist mill cracking open the husks of the kernels which helps expose the starches during the mashing process. Place the pasty banana container full into a cheesecloth and squeeze out the juice into a catch jar.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title steps to brew beer by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.