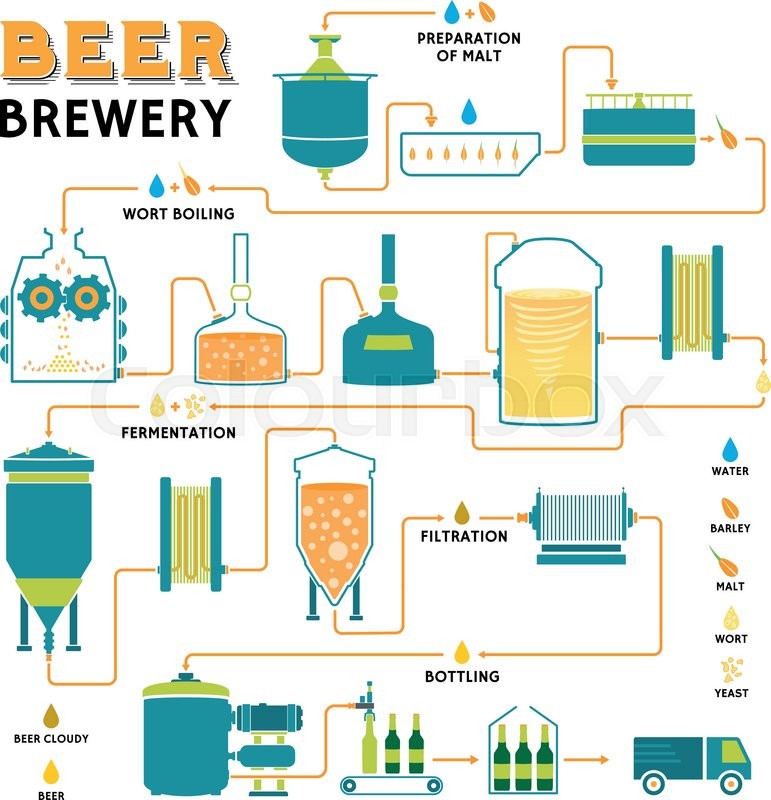

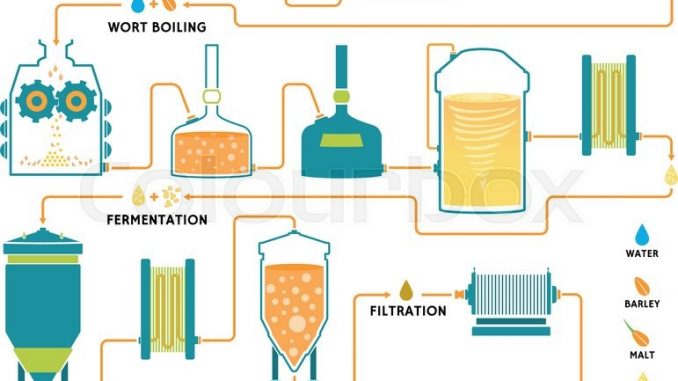

Steps for brewing beer

Steps For Brewing Beer. The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. Once the beer is done fermenting youll need to either keg your beer or prime the beer and get it ready to bottle. Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat. Dave adds a couple of bonuses to not leave anyone hanging when making their beer like the BARE BONES DIRECTIONS Step by Step Checklist and 40 easy to make beers.

Beer Production Steps Hand Drawn Pictures Of Brewery Vector Royalty Free Cliparts Vectors And Stock Illustration Image 110438506 From 123rf.com

Beer Production Steps Hand Drawn Pictures Of Brewery Vector Royalty Free Cliparts Vectors And Stock Illustration Image 110438506 From 123rf.com

Youll need a bottling bucket that you can attach a filler tube. Once the solution becomes clear throw in the syrup into your bottling bucket so when you fill it up with beer. Gather your brewing equipment. There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel. As you heat your water steep your. Brewing is a complex fermentation process.

Achetez neuf ou doccasion.

It differs from other industrial fermentation because flavor aroma clarity color foam production foam stability and percentage of alcohol are the factors associated with finished product. Dont forget to. Before transferring your beer from the fermenter prepare your priming solution by mixing in corn sugar with enough water to cover it about a cup and heat it up in the microwave. Now pour up to 2 12 gallons of the remaining water into your brew pot leaving at least 3 inches to the top of the pot. He covers the legalities beer basics the varieties of beer you can make the equipment necessary for brewing beer from home the ingredients for good beer proper fermenting and even bottling and aging your beer. Steps involved in beer production are.

Source: pinterest.com

Source: pinterest.com

The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. How to Make Beer Step 1. The sugar-water saturate is drained off from grains. As you heat your water steep your. Fill your 5-gallon brew kettle with 25 gallons of water.

Source: aslanbrewing.com

Source: aslanbrewing.com

It differs from other industrial fermentation because flavor aroma clarity color foam production foam stability and percentage of alcohol are the factors associated with finished product. There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel. The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. Gather your brewing equipment. Dave adds a couple of bonuses to not leave anyone hanging when making their beer like the BARE BONES DIRECTIONS Step by Step Checklist and 40 easy to make beers.

Source: chinabrewingequipment.com

Source: chinabrewingequipment.com

Add your crushed grains. After 30 minutes remove the grain bag and discard. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100. Steps involved in beer production are. 4 Simple Steps To Your First Home Brew - With 40 Easy Peasy Recipes et des millions de livres en stock sur Amazonfr.

Source: vectorstock.com

Source: vectorstock.com

Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat. Brewing is a complex fermentation process. There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel. As you heat your water steep your. He covers the legalities beer basics the varieties of beer you can make the equipment necessary for brewing beer from home the ingredients for good beer proper fermenting and even bottling and aging your beer.

Source: foodcrumbles.com

Source: foodcrumbles.com

Important steps in the beer brewing process are fermentation and storage. As you heat your water steep your. There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel. Once the beer is done fermenting youll need to either keg your beer or prime the beer and get it ready to bottle. Fill your 5-gallon brew kettle with 25 gallons of water.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Add your crushed grains. Once the solution becomes clear throw in the syrup into your bottling bucket so when you fill it up with beer. Dont forget to. Fill your 5-gallon brew kettle with 25 gallons of water. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100.

Source: thesciencenotes.com

Source: thesciencenotes.com

Dont forget to. Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat. The sugar-water saturate is drained off from grains. Gather your brewing equipment. Steps involved in beer production are.

Source: pinterest.com

Source: pinterest.com

Youll need a bottling bucket that you can attach a filler tube. Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat. Beer is produced from barley grains. Fill your 5-gallon brew kettle with 25 gallons of water. The sugar-water saturate is drained off from grains.

![]() Source: northernbrewer.com

Source: northernbrewer.com

After 30 minutes remove the grain bag and discard. Add your grain bag cover with the kettle lid and let everything steep for 30 minutes. Brewing is a complex fermentation process. 4 Simple Steps To Your First Home Brew - With 40 Easy Peasy Recipes et des millions de livres en stock sur Amazonfr. There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel.

Source: 123rf.com

Source: 123rf.com

Important steps in the beer brewing process are fermentation and storage. After 30 minutes remove the grain bag and discard. Beer is produced from barley grains. If gathering all of that sounds like too much work simply choose. He covers the legalities beer basics the varieties of beer you can make the equipment necessary for brewing beer from home the ingredients for good beer proper fermenting and even bottling and aging your beer.

Source: pinterest.com

Source: pinterest.com

There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel. He covers the legalities beer basics the varieties of beer you can make the equipment necessary for brewing beer from home the ingredients for good beer proper fermenting and even bottling and aging your beer. Dave adds a couple of bonuses to not leave anyone hanging when making their beer like the BARE BONES DIRECTIONS Step by Step Checklist and 40 easy to make beers. Once the solution becomes clear throw in the syrup into your bottling bucket so when you fill it up with beer. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100.

Source: visual.ly

Source: visual.ly

There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel. Beer is produced from barley grains. Steps involved in beer production are. How to Make Beer Step 1. There are 2 ways of mashing namely infusion mashing grains are heated in one vessel and decoction mashing a little portion is heated and then introduced back into the original vessel.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Youll need a bottling bucket that you can attach a filler tube. Beer is produced from barley grains. Before transferring your beer from the fermenter prepare your priming solution by mixing in corn sugar with enough water to cover it about a cup and heat it up in the microwave. Add your crushed grains. Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat.

Source: shutterstock.com

Source: shutterstock.com

He covers the legalities beer basics the varieties of beer you can make the equipment necessary for brewing beer from home the ingredients for good beer proper fermenting and even bottling and aging your beer. Heat a few quarts of water in your brew kettle to 160F 71C then turn off the heat. Add your grain bag cover with the kettle lid and let everything steep for 30 minutes. Now pour up to 2 12 gallons of the remaining water into your brew pot leaving at least 3 inches to the top of the pot. Youll need a bottling bucket that you can attach a filler tube.

Source: birrificio.it

Source: birrificio.it

4 Simple Steps To Your First Home Brew - With 40 Easy Peasy Recipes et des millions de livres en stock sur Amazonfr. Once the beer is done fermenting youll need to either keg your beer or prime the beer and get it ready to bottle. Achetez neuf ou doccasion. Important steps in the beer brewing process are fermentation and storage. Add your grain bag cover with the kettle lid and let everything steep for 30 minutes.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title steps for brewing beer by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.