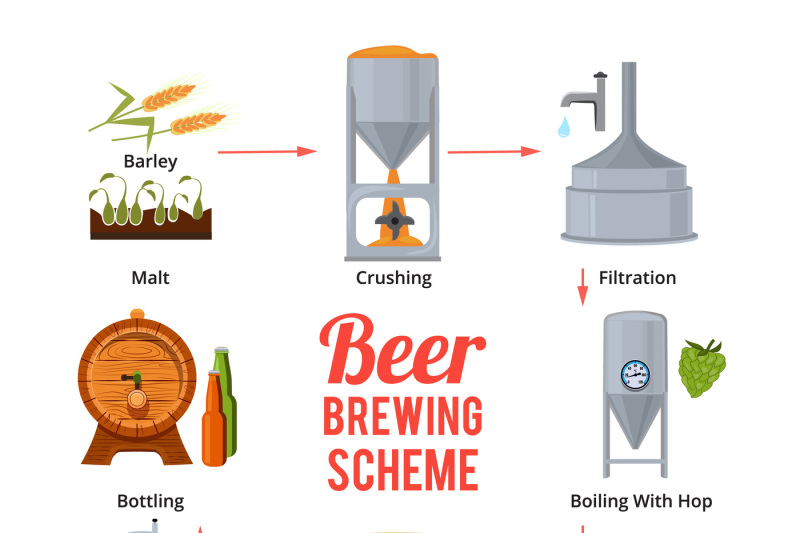

Stages of brewing beer

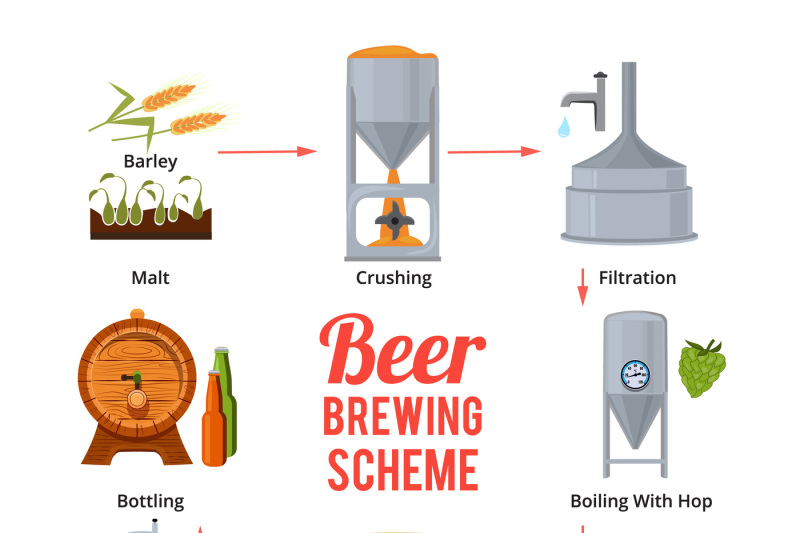

Stages Of Brewing Beer. The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail. Generally breweries operate within 7 steps which. Barley malt makes up the body of the beer and typically 200 g of barley malt is needed to make a litre of beer. Brewers considers these parameters to ensure the perfect beer brewing process.

Stages Of Beer Production Vector Symbols Of Brewery By Onyx Thehungryjpeg Com From thehungryjpeg.com

Stages Of Beer Production Vector Symbols Of Brewery By Onyx Thehungryjpeg Com From thehungryjpeg.com

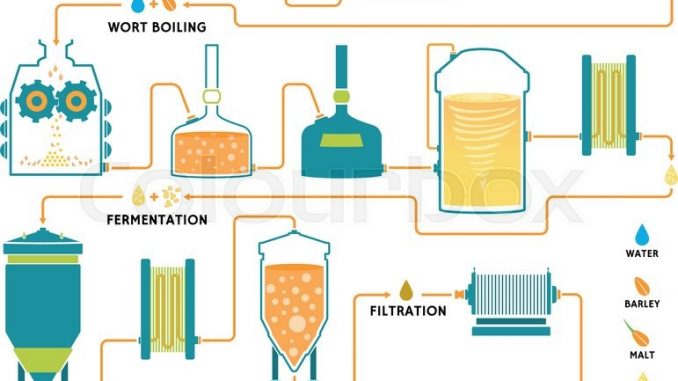

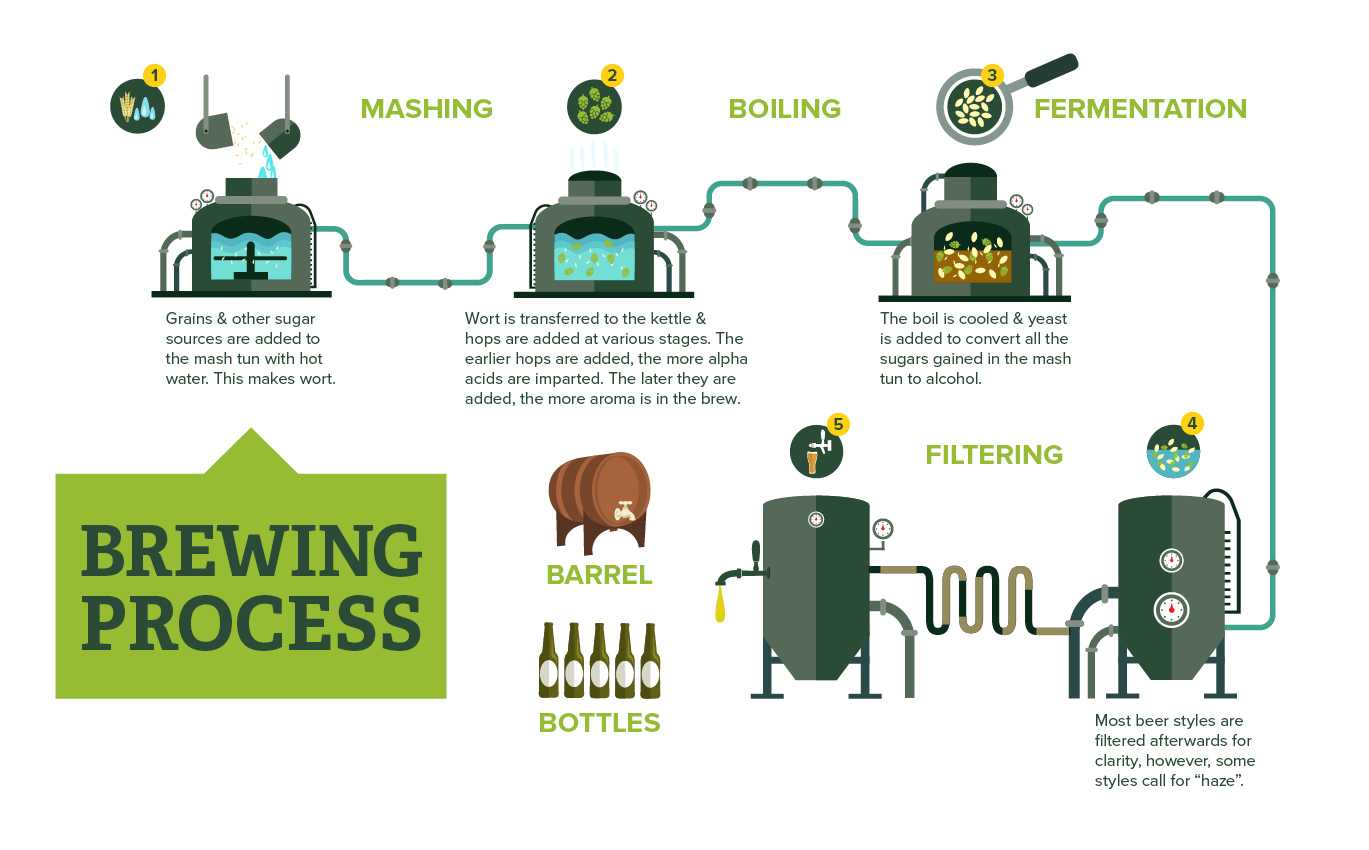

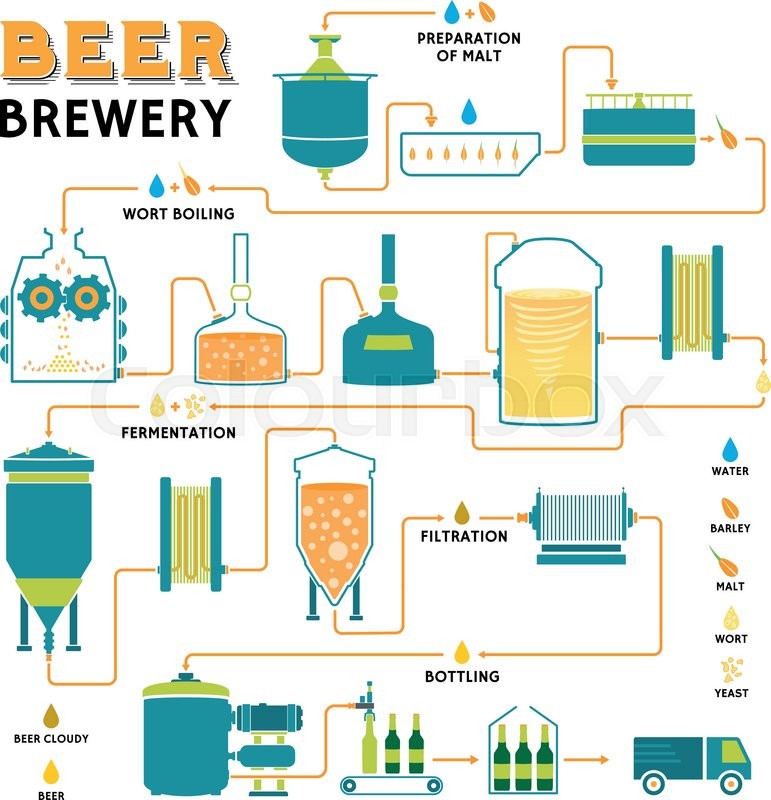

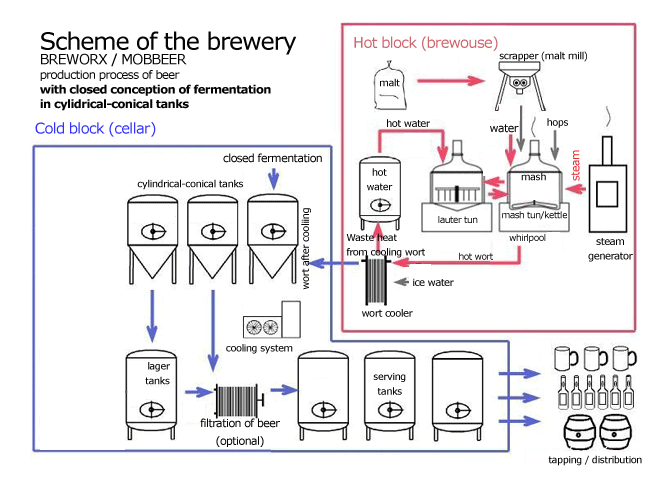

Generally breweries operate within 7 steps which. The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail. At the brewery the malt is sent through a grist mill cracking open the husks of the kernels which helps expose the starches during the mashing process. Bottom line breweries are merely places where beers are made. Steps involved in beer production are. Recipe from a trusted source or high-quality kit Wort Production.

The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail.

Steps involved in beer production are. The grain is then dried in a kiln and sometimes roasted a process that usually takes place in a separate location from the brewery. Bottom line breweries are merely places where beers are made. Barley malt makes up the body of the beer and typically 200 g of barley malt is needed to make a litre of beer. Chlorine-free water carbon filtered well spring RO or distilled Boil. These stages and procedure starts with the cleaning operations of the sorghum used which is the main raw material for brewing and then to other stages such as mashing filtration centrifugation sparging lagering bottling pasteurization packaginglabeling and final delivery to the consumer.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

These magical breweries merely work within the bounds of the process specifying the levels and processes of making beer. Brewers considers these parameters to ensure the perfect beer brewing process. The brewing process begins with malting milling mashing and lautering. Steeped specialty grains and malt extract Water. Chlorine-free water carbon filtered well spring RO or distilled Boil.

Source: 123rf.com

Source: 123rf.com

Beer is produced from barley grains. We begin the beer making process with the mash which is the name of the slurry formed from mixing barley malt and water. Beer Brewing Steps Step 1. Partial boil staggered extract additions for pale beers. Indian beer bands with alcohol content by volume.

Source: birrificio.it

Source: birrificio.it

The first thing you need to do when making a beer is to soak ripe grains in the water you change daily. Or if youre a Canadian brewing beer in the winter just put the pot outside for a few hours. The brewing process begins with malting milling mashing and lautering. The process of steep. Traditionally homebrewers use copper pots for brewing.

Source: aslanbrewing.com

Source: aslanbrewing.com

Brewers considers these parameters to ensure the perfect beer brewing process. Since lambic must undergo several months or even several. When harvested grain maltusually barleyarrives at the brewing facility it is crushed. Bottom line breweries are merely places where beers are made. Barley malt makes up the body of the beer and typically 200 g of barley malt is needed to make a litre of beer.

Source: wiki.anton-paar.com

Source: wiki.anton-paar.com

Or if youre a Canadian brewing beer in the winter just put the pot outside for a few hours. The Four Stages of Homebrewing Beginner I hope it turns out well Recipe. The grain is then dried in a kiln and sometimes roasted a process that usually takes place in a separate location from the brewery. Brewing is a complex fermentation process. The Complete Brewing Process Step 1.

Source: allthingstreasurecoast.com

Source: allthingstreasurecoast.com

Once the wort has cooled remove some wort to calculate your original gravity with a hydrometer only required if you want to know the final alcohol level Start by sterilizing the yeast package the mixing spoon and EVERYTHING that touches the beer after this point. Brewing is a complex fermentation process. It is time to brew the wort. The process of steep. The grist is then transferred into.

Source: usahops.org

Source: usahops.org

Barley malt makes up the body of the beer and typically 200 g of barley malt is needed to make a litre of beer. Since lambic must undergo several months or even several. Beer Brewing Steps Step 1. Generally breweries operate within 7 steps which. Traditionally homebrewers use copper pots for brewing.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Partial boil staggered extract additions for pale beers. These stages and procedure starts with the cleaning operations of the sorghum used which is the main raw material for brewing and then to other stages such as mashing filtration centrifugation sparging lagering bottling pasteurization packaginglabeling and final delivery to the consumer. The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail. It differs from other industrial fermentation because flavor aroma clarity color foam production foam stability and percentage of alcohol are the factors associated with finished product. Once the wort has cooled remove some wort to calculate your original gravity with a hydrometer only required if you want to know the final alcohol level Start by sterilizing the yeast package the mixing spoon and EVERYTHING that touches the beer after this point.

Source: thehungryjpeg.com

Source: thehungryjpeg.com

It is time to brew the wort. Or if youre a Canadian brewing beer in the winter just put the pot outside for a few hours. The first thing you need to do when making a beer is to soak ripe grains in the water you change daily. These stages and procedure starts with the cleaning operations of the sorghum used which is the main raw material for brewing and then to other stages such as mashing filtration centrifugation sparging lagering bottling pasteurization packaginglabeling and final delivery to the consumer. In this vessel the grist mixes with hot.

Source: czechminibreweries.com

Source: czechminibreweries.com

Brewing is a complex fermentation process. Since lambic must undergo several months or even several. When harvested grain maltusually barleyarrives at the brewing facility it is crushed. The grist moves to a large tank called a mash tun. Bottom line breweries are merely places where beers are made.

Source: vectorstock.com

Source: vectorstock.com

In this vessel the grist mixes with hot. The brewing process could be helped with in a small unused garage or in a city block-wide brewery area. Partial boil staggered extract additions for pale beers. STAGE 3 Maturation STAGE 4 Blending STAGE 5 Bottling After the fermentation process it is time for the maturation process which lasts at least six additional months but which can also last for several years. Steeped specialty grains and malt extract Water.

Source: dreamstime.com

Source: dreamstime.com

The brewing process could be helped with in a small unused garage or in a city block-wide brewery area. Brewing is a complex fermentation process. Beginning In the brew house different types of malt are crushed together to break up the. The brewing process begins with malting milling mashing and lautering. The Complete Brewing Process Step 1.

Source: pinterest.at

Source: pinterest.at

Beginning In the brew house different types of malt are crushed together to break up the. Once the wort has cooled remove some wort to calculate your original gravity with a hydrometer only required if you want to know the final alcohol level Start by sterilizing the yeast package the mixing spoon and EVERYTHING that touches the beer after this point. Indian beer bands with alcohol content by volume. The grain is then dried in a kiln and sometimes roasted a process that usually takes place in a separate location from the brewery. Learn the Step-by-Step Process Of Brewing Beer Explained in Animated GIFs Step 1.

Source: researchgate.net

Source: researchgate.net

In this vessel the grist mixes with hot. The amount of barley malt added to the water determines the strength of the resultant beer and the type of malt rice corn or wheat used controls the colour of the final product. We begin the beer making process with the mash which is the name of the slurry formed from mixing barley malt and water. Recipe from a trusted source or high-quality kit Wort Production. The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail.

Source: researchgate.net

Source: researchgate.net

The Complete Brewing Process Step 1. The grist is then transferred into. The brewing process could be helped with in a small unused garage or in a city block-wide brewery area. The process of steep. At the brewery the malt is sent through a grist mill cracking open the husks of the kernels which helps expose the starches during the mashing process.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title stages of brewing beer by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.