Craft beer brewing process

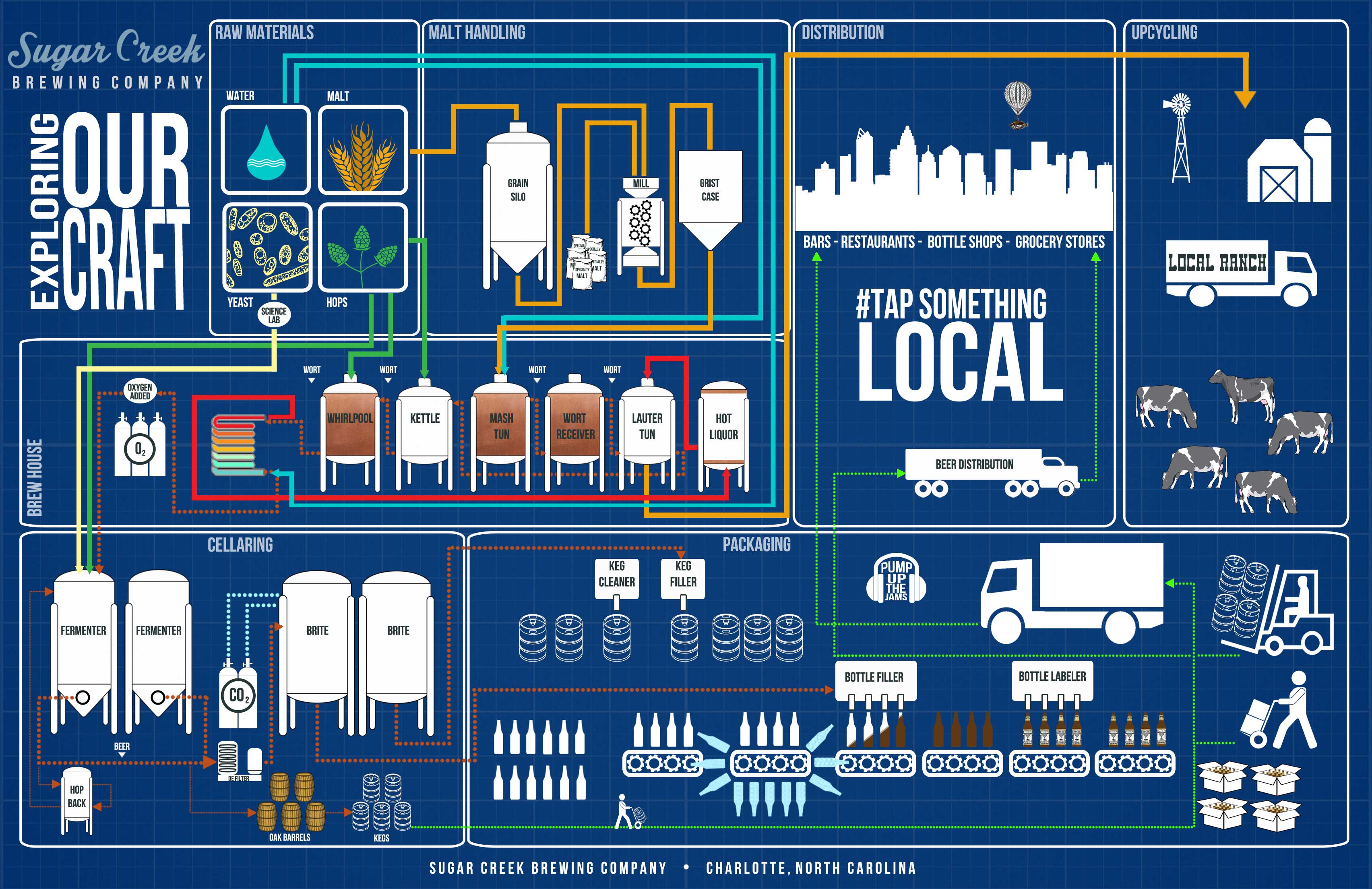

Craft Beer Brewing Process. Lautering is the separation of the extracts won during mashing from the spent grain. The process of brewing all begins in the brewery with crushing whole grain malt with a mill. A batch process takes place in individual vessels such as a lauter tun or a fermenting vessel. Bridging the gap between brewing theory and practical craft brewing comes from the experience to spot signs of trouble and the knowhow to respond to them.

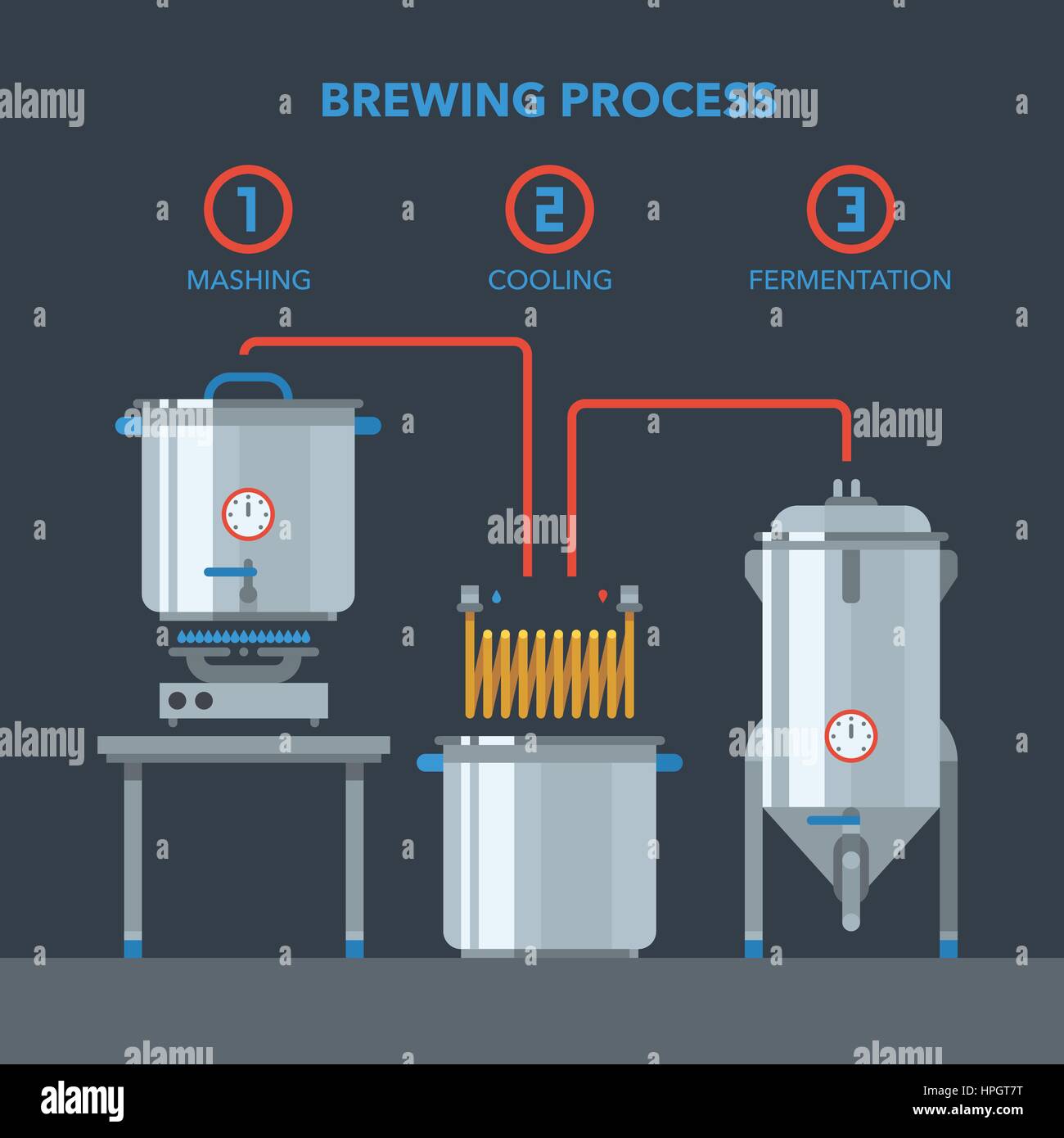

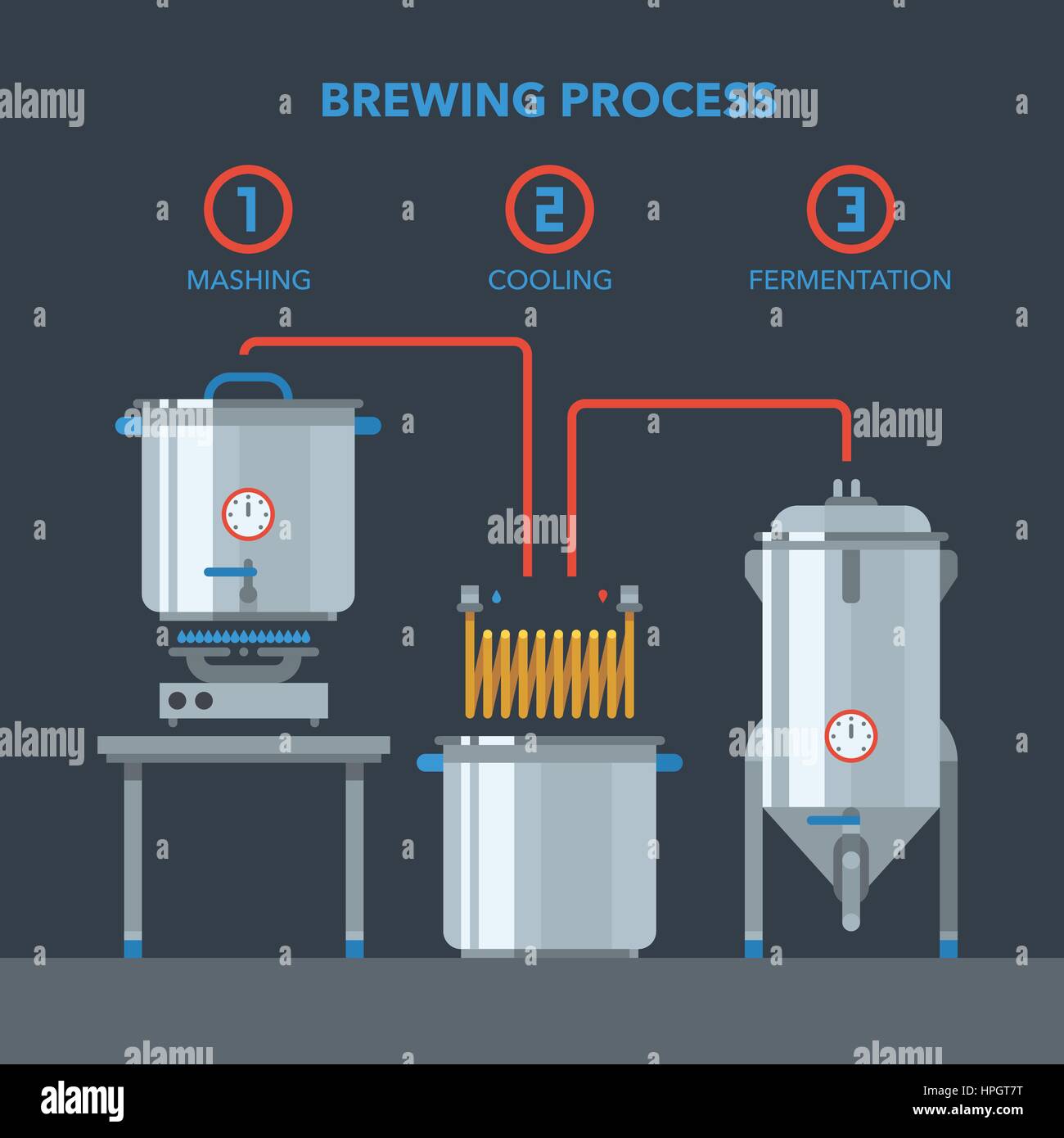

Home Brewing Process Items All You Need For Brew Home Made Craft Beer Elements For Home Brewery Mashing Cooling Fermentation Creative Vector Inf Stock Vector Image Art Alamy From alamy.com

Home Brewing Process Items All You Need For Brew Home Made Craft Beer Elements For Home Brewery Mashing Cooling Fermentation Creative Vector Inf Stock Vector Image Art Alamy From alamy.com

The craft of making beer blends complex processes with creative artistry. THE BREWING PROCESS MILLING. Issues can be controllable and avoidable given the right brewing equipment. Together we quickly improved our brewing process resulting in great craft style beers. Quality for this purpose has been defined as. We also incorporate a variety of specialty grains into our kits which add to the complexity and color of the beer.

Beer is more than just water hops malt and yeast.

A chiller is involved in more steps of the beer making process than you think. Non-craft brewing alcoholic beverage industry member. Mashing is the process of mixing milled grain typically malted grain with water and heating this mixture. We have gained a tremendous amount of experience in the trade of beer brewing by individually specializing on a specific part of the brewing process. The Brewing Process 21 Mashing. A beer that is responsibly produced using wholesome ingredients consistent brewing techniques and good manufacturing practices which exhibits flavor characteristics that are consistently aligned with both the brewers and the beer drinkers.

Source: craftbeeracademy.com

Source: craftbeeracademy.com

Each process is normally started and finished in. Batch Process is the name given to the process of producing a beer in individual processes vessels and time frames as opposed to a continuous process that involves a steady flow of ingredients through the plant and equipment. Learn the Step-by-Step Process Of Brewing Beer Explained in Animated GIFs Step 1. A batch process takes place in individual vessels such as a lauter tun or a fermenting vessel. Lautering is the separation of the extracts won during mashing from the spent grain.

Source: aslanbrewing.com

Source: aslanbrewing.com

Bridging the gap between brewing theory and practical craft brewing comes from the experience to spot signs of trouble and the knowhow to respond to them. The grist is then transferred into. A chiller is involved in more steps of the beer making process than you think. We also incorporate a variety of specialty grains into our kits which add to the complexity and color of the beer. Bridging the gap between brewing theory and practical craft brewing comes from the experience to spot signs of trouble and the knowhow to respond to them.

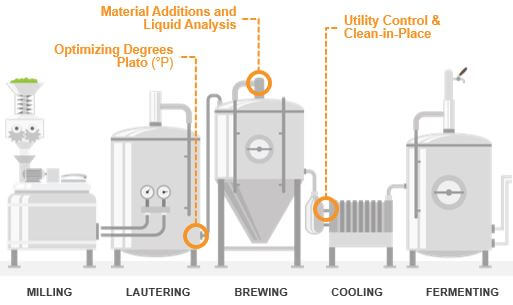

Source: wiki.anton-paar.com

Source: wiki.anton-paar.com

We have gained a tremendous amount of experience in the trade of beer brewing by individually specializing on a specific part of the brewing process. Brewery process knowledge and craft brewing solutions Alfa Laval offers craft beer process equipment and services for independent local producers and global craft breweries to improve beer quality optimize production and reduce costs and environmental impacts. A chiller is involved in more steps of the beer making process than you think. At this point it can be said that the brewing process has ended and the fermentation process. They often take classic old-world styles from great brewing countries like England Germany and Belgium and add their own twists by modifying the amount or type of ingredients or the brewing processes.

Source: dreamstime.com

Source: dreamstime.com

A batch process takes place in individual vessels such as a lauter tun or a fermenting vessel. Together we quickly improved our brewing process resulting in great craft style beers. This is the process of mixing the crushed malt with very. The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail. Today craft breweries make up about 4 of.

Source: emersonautomationexperts.com

Source: emersonautomationexperts.com

Due to the popularity of craft beer in America there are. The brewery will or should - retain the beer for as long as it takes for everything to reach a peak. Today craft breweries make up about 4 of. Due to the popularity of craft beer in America there are. Quality for this purpose has been defined as.

Source: foghornbrewhouse.com.au

Source: foghornbrewhouse.com.au

It is achieved in. The aim of this final part of the brewing procedure is to let the aromas and flavours of the beer it is now beer develop and round out over time. Due to the popularity of craft beer in America there are. Brewery process knowledge and craft brewing solutions Alfa Laval offers craft beer process equipment and services for independent local producers and global craft breweries to improve beer quality optimize production and reduce costs and environmental impacts. The craft of making beer blends complex processes with creative artistry.

Source: pinterest.at

Source: pinterest.at

The Importance of the Cooling and Glycol Systems in Your Craft Brewery by Jim VanderGiessen Jr. Once milling is complete mashing begins. Quality for this purpose has been defined as. Beginning In the brew house different types of malt are crushed together to break up the. Issues can be controllable and avoidable given the right brewing equipment.

Source: zapfler-craft-beer.com

Source: zapfler-craft-beer.com

Lautering is the separation of the extracts won during mashing from the spent grain. The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail. Brewery 22four was founded in the summer of 2020. The craft of making beer blends complex processes with creative artistry. At this point it can be said that the brewing process has ended and the fermentation process.

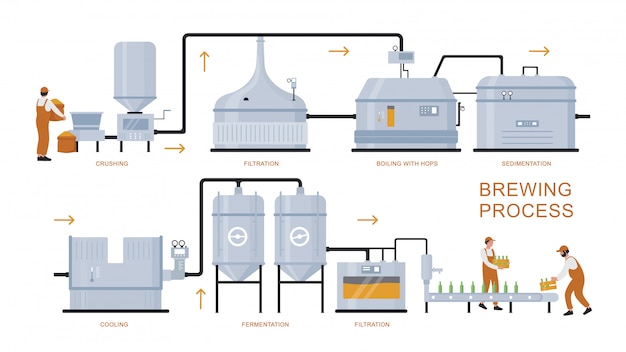

Source: freepik.com

Source: freepik.com

The brewery will or should - retain the beer for as long as it takes for everything to reach a peak. A batch process takes place in individual vessels such as a lauter tun or a fermenting vessel. Brewery process knowledge and craft brewing solutions Alfa Laval offers craft beer process equipment and services for independent local producers and global craft breweries to improve beer quality optimize production and reduce costs and environmental impacts. The process of brewing all begins in the brewery with crushing whole grain malt with a mill. In the beer making process various ingredients are mixed processed and sometimes the structure of the raw materials is altered.

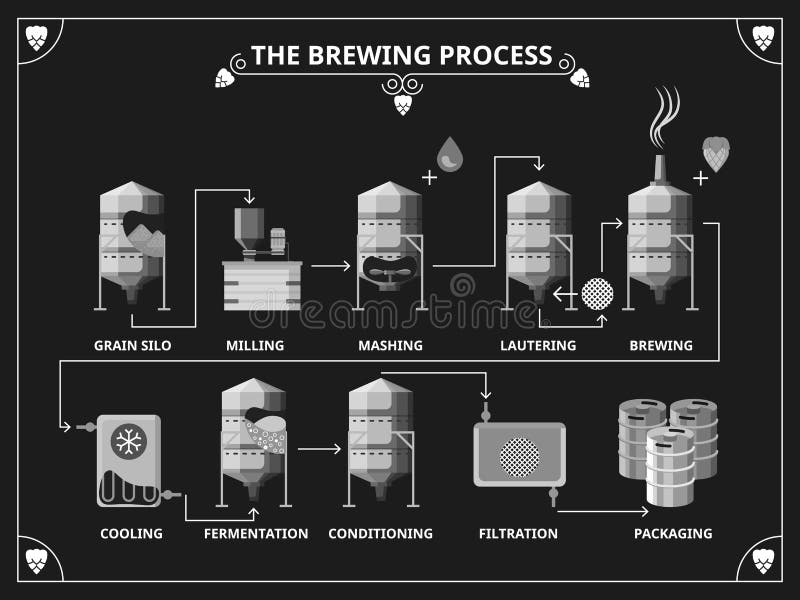

Source: dreamstime.com

Source: dreamstime.com

The conditioning stage can last from a few days through to months or even years in barrels. Brewery 22four was founded in the summer of 2020. Beginning In the brew house different types of malt are crushed together to break up the. The cooled wort enters a fermentation vessel where yeast is added. We also incorporate a variety of specialty grains into our kits which add to the complexity and color of the beer.

Source: pinterest.com

Source: pinterest.com

Mashing is the process of mixing milled grain typically malted grain with water and heating this mixture. Non-craft brewing alcoholic beverage industry member. THE BREWING PROCESS MILLING. We also incorporate a variety of specialty grains into our kits which add to the complexity and color of the beer. Beer Styles Craft brewers use a wide variety of ingredients to achieve the aroma body flavor and finish they desire in their beer.

Source: craftbeeracademy.com

Source: craftbeeracademy.com

Mashing is the process of mixing milled grain typically malted grain with water and heating this mixture. The all-grain brewing process generally takes 3 hours while extract brewing takes about 90 minutes without compromising quality or taste. Issues can be controllable and avoidable given the right brewing equipment. Brewing with all grain the biggest being time and convenience. Lautering is the separation of the extracts won during mashing from the spent grain.

Source: sugarcreekbrewing.com

Source: sugarcreekbrewing.com

The brewery will or should - retain the beer for as long as it takes for everything to reach a peak. The craft of making beer blends complex processes with creative artistry. Quality for this purpose has been defined as. Together we quickly improved our brewing process resulting in great craft style beers. We have gained a tremendous amount of experience in the trade of beer brewing by individually specializing on a specific part of the brewing process.

Source: banke-ps.de

Source: banke-ps.de

The aim of this final part of the brewing procedure is to let the aromas and flavours of the beer it is now beer develop and round out over time. Once milling is complete mashing begins. Due to the popularity of craft beer in America there are. We have gained a tremendous amount of experience in the trade of beer brewing by individually specializing on a specific part of the brewing process. A beer that is responsibly produced using wholesome ingredients consistent brewing techniques and good manufacturing practices which exhibits flavor characteristics that are consistently aligned with both the brewers and the beer drinkers.

Source: alamy.com

Source: alamy.com

We have gained a tremendous amount of experience in the trade of beer brewing by individually specializing on a specific part of the brewing process. Each process is normally started and finished in. Brewery process knowledge and craft brewing solutions Alfa Laval offers craft beer process equipment and services for independent local producers and global craft breweries to improve beer quality optimize production and reduce costs and environmental impacts. This is the process of mixing the crushed malt with very. The Quality Subcommittee envisions a membership that consistently produces beer of high quality.

If you find this site convienient, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title craft beer brewing process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.