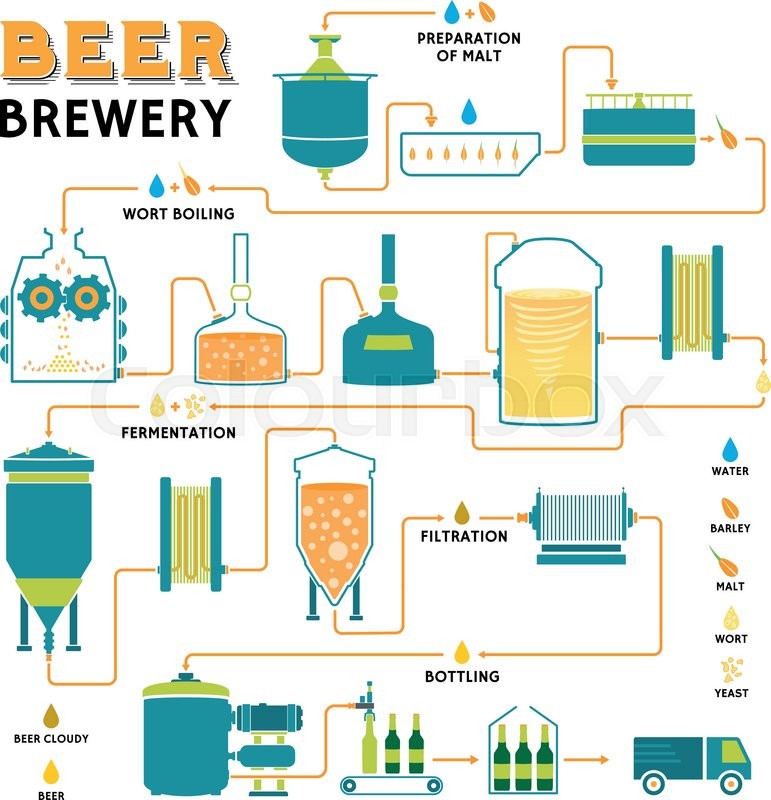

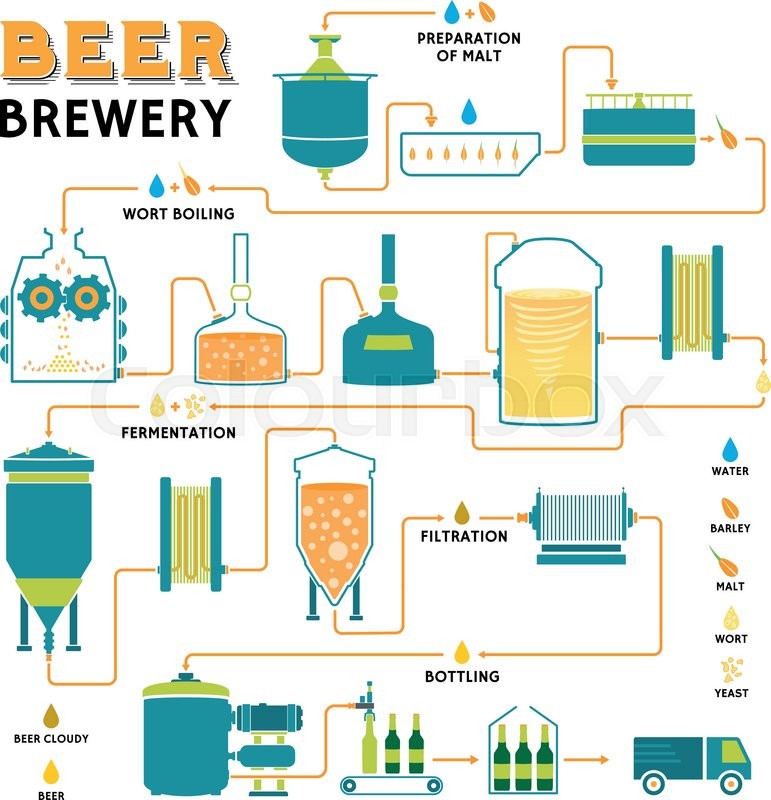

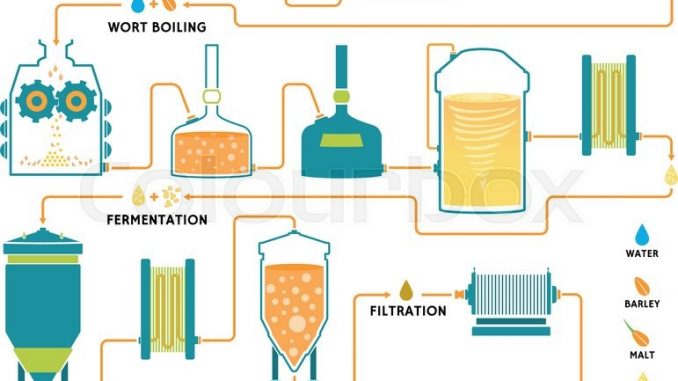

Brewing beer process step by step

Brewing Beer Process Step By Step. This is just an introduction to brewing. Youll also become like Bacchus to your beer buddies. When harvested grain maltusually barleyarrives at the brewing facility it is crushed. We have created this step-by-step guide to ensure that the final step in your homebrew goes seamlessly.

Brewing Beer Production Process Online Biology Notes From onlinebiologynotes.com

Brewing Beer Production Process Online Biology Notes From onlinebiologynotes.com

2 quarts water 6 ounces dry. Here is a step-by-step guide to mash. Besides serving as a brand ambassador your business website is also a great venue for attracting a wider customer base. The brewing process step by stepWeve tried to simplify the brewing process as much as possible for first time brewers. Mashing causes the natural enzymes in the malt to break down starches converting them. The aim of malting is to isolate the enzymes needed for brewing.

This is just an introduction to brewing.

Brewing is a complex fermentation process. Share your brewing process and philosophy as a brewer. Tuck the beer away in a place that keeps at around 60-70F to let it carbonate. Congratulations youve brewed your first batch of homebrew. Vigorously stir the yeast into the wort. The aim of malting is to isolate the enzymes needed for brewing.

Source: pinterest.com

Source: pinterest.com

The grist is then transferred into. Strong copy describing your beers along with enticing photography will make consumers want to give them a try. The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. In this first step of the beer-making process the yeast cells get a head start hungrily dividing and populating as they feast on dry malt extract. Beer is produced from barley grains.

Source: pinterest.com

Source: pinterest.com

In this vessel the grist mixes with hot. Beginning In the brew house different types of malt are crushed together to break up the. Then store your bucket at 60-70 F for ales or 45-55 F for lagers. This is just an introduction to brewing. Brewing is a complex fermentation process.

Source: foodcrumbles.com

Source: foodcrumbles.com

The grist is then transferred into. The process of the yeast metabolization is what will turn wort the liquid extracted from the mashing process into beer. To ferment your brew you want to use a plastic lid with a grommet drilled hole and place an airlock in it. After a few weeks you can crack open a bottle and gently pour it into a glass you can leave the last couple of yeasty ounces in the bottle and swig it afterwards. Steps involved in beer production are.

Youll also become like Bacchus to your beer buddies. Ferment Your Home Brew. Steps involved in beer production are. The grist is then transferred into. If you are using a carboy then get a rubber stopper with a hole to place your airlock over it.

Source: en.wikipedia.org

Source: en.wikipedia.org

It differs from other industrial fermentation because flavor aroma clarity color foam production foam stability and percentage of alcohol are the factors associated with finished product. After a few weeks you can crack open a bottle and gently pour it into a glass you can leave the last couple of yeasty ounces in the bottle and swig it afterwards. When harvested grain maltusually barleyarrives at the brewing facility it is crushed. Ferment Your Home Brew. In this first step of the beer-making process the yeast cells get a head start hungrily dividing and populating as they feast on dry malt extract.

Source: visual.ly

Source: visual.ly

Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100 degrees Fahrenheit up to 170 degrees Fahrenheit. If you are using a carboy then get a rubber stopper with a hole to place your airlock over it. Besides serving as a brand ambassador your business website is also a great venue for attracting a wider customer base. The barley grains are then passed through grist mills to form grits. Congratulations youve brewed your first batch of homebrew.

Source: thesciencenotes.com

Source: thesciencenotes.com

How to Bottle Beer in 9 Steps. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100 degrees Fahrenheit up to 170 degrees Fahrenheit. Beer bottles about 48 12-oz bottles for a 5-gallon batch. Tuck the beer away in a place that keeps at around 60-70F to let it carbonate. Besides serving as a brand ambassador your business website is also a great venue for attracting a wider customer base.

Source: pinterest.com

Source: pinterest.com

Brewing your own beer at home is easy inexpensive fun and will most likely produce a brew far superior to that watery canned stuff. The barley grains are then passed through grist mills to form grits. The process of the yeast metabolization is what will turn wort the liquid extracted from the mashing process into beer. The goal is to mix some oxygen in for the yeast. If you are using a carboy then get a rubber stopper with a hole to place your airlock over it.

![]() Source: northernbrewer.com

Source: northernbrewer.com

Besides serving as a brand ambassador your business website is also a great venue for attracting a wider customer base. Steps involved in beer production are. After a few weeks you can crack open a bottle and gently pour it into a glass you can leave the last couple of yeasty ounces in the bottle and swig it afterwards. When harvested grain maltusually barleyarrives at the brewing facility it is crushed. Share your brewing process and philosophy as a brewer.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

How to Bottle Beer in 9 Steps. Strong copy describing your beers along with enticing photography will make consumers want to give them a try. Different types of yeast will determine whether the beer is considered a lager or an ale. The goal is to mix some oxygen in for the yeast. Well lay out the basic steps.

Source: brewsavor.com

Source: brewsavor.com

In this first step of the beer-making process the yeast cells get a head start hungrily dividing and populating as they feast on dry malt extract. The grist moves to a large tank called a mash tun. How to Bottle Beer in 9 Steps. Start by sterilizing the yeast package the mixing spoon and EVERYTHING that touches the beer after this point. Different types of yeast will determine whether the beer is considered a lager or an ale.

Source: aslanbrewing.com

Source: aslanbrewing.com

Brewing is a complex fermentation process. Here is a step-by-step guide to mash. We have created this step-by-step guide to ensure that the final step in your homebrew goes seamlessly. Well lay out the basic steps. Write copy with your target consumer in mind.

Source: 123rf.com

Source: 123rf.com

To ferment your brew you want to use a plastic lid with a grommet drilled hole and place an airlock in it. Write copy with your target consumer in mind. How to Bottle Beer in 9 Steps. Mashing is the process of combining the grist and water also known as liquor and heating it to temperatures usually between 100 degrees Fahrenheit up to 170 degrees Fahrenheit. Youll also become like Bacchus to your beer buddies.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

The grist moves to a large tank called a mash tun. The barley grains are then passed through grist mills to form grits. Beer is produced from barley grains. Ferment Your Home Brew. Besides serving as a brand ambassador your business website is also a great venue for attracting a wider customer base.

Source: pinterest.com

Source: pinterest.com

2 quarts water 6 ounces dry. Different types of yeast will determine whether the beer is considered a lager or an ale. To ferment your brew you want to use a plastic lid with a grommet drilled hole and place an airlock in it. The first step in the beer-making process is mashing in which the grist or milled malt is transferred to the mash tun. Tuck the beer away in a place that keeps at around 60-70F to let it carbonate.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title brewing beer process step by step by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.